Raising the bar in China's auto industry

Updated: 2013-04-19 13:11

|

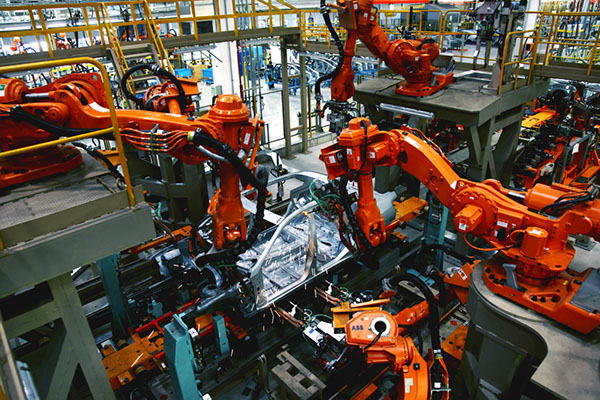

The assembly line at Beijing Benz Automotive Co Ltd. [Photo / China Daily] |

Notably, locally-produced vehicles are sent to Germany every year to conduct a series of comparison testing.

The results of this testing prove that the Mercedes-Benz cars produced by BBAC are at the same quality level as other Daimler plants worldwide.

As throughout every division of Daimler, personnel training and international know-how transfer is the foundation for consistent high standards. Each year, BBAC employees are sent to Daimler's German training centers, and Daimler employees are continuously present at BBAC to extend further guidance and support for on-the-job training.

Greener cars through green production

Producing cars in-line with Daimler's value of sustainable mobility, the BBAC plant itself embodies the latest in "green production".

"The plant was built from scratch as a green-field project," explained Deiss. "With breakthroughs in operational designs and huge investments, we've developed one of the most advanced auto manufacturing facilities in China that sets a benchmark for sustainability efforts within the industry."

Back in 2005, when its facilities were being set up, BBAC invested in "isolation layers" beneath its shop floors to maintain a gap that protects the ground below from being polluted. This ecological measure demonstrated BBAC's commitment to become the industry pioneer in "green production".

|

Welding Workshop at BBAC. [Photo / China Daily] |

As part of its energy-saving efforts, BBAC installed solar panels on the roof of its new assembly shop to generate more than 3 million kilowatt-hours of electricity a year, equivalent to saving 1,200 tons of coal consumption and about 3,000 tons of carbon dioxide emissions per year.

In addition, this new assembly shop is designed with a geo-exchange heating and cooling system which helps to reduce the emission of carbon and reduces total energy consumption by 40 percent.

BBAC's rainwater collection system covers 1.6 million square meters of its facilities and minimizes water consumption by allowing up to 800,000 tons to be reused annually - a significant contribution to social responsibility. And to further minimize the emission of volatile solvents harmful to the environment during the vehicle painting process, BBAC will be applying a state-of-the-art process to its new paint shop to dispose of pollutants by condensation and then combustion, bringing the added benefit of converting pollutants to heat energy for reuse.

Even the small details have been worth working on: the company has replaced halogen lamps with Low Voltage Discharge Lamps to save over 50 percent of lighting costs.

BBAC aims to continue investing in the installation of environment-friendly technology in its manufacturing facilities, with a longer-term green strategy representing Daimler's trusted and sustainable partnerships in China.

|

|